Most of us don’t even know that carbon monoxide (CO) is one of the prominent causes of workplace poisoning and the resulting fatalities globally. Our industries are filled with machinery and processes that emit carbon monoxide, the silent killer. To prevent this silent killer, whose small amount can also be fatal, our industries should employ a Carbon Monoxide (CO) Gas Detector.

What is carbon monoxide? Remember this: it is a highly poisonous, colorless, and odorless byproduct that human beings can’t detect without actually getting poisoned. A carbon monoxide gas detector helps humans identify a potential CO gas leak so we can take necessary preventative actions.

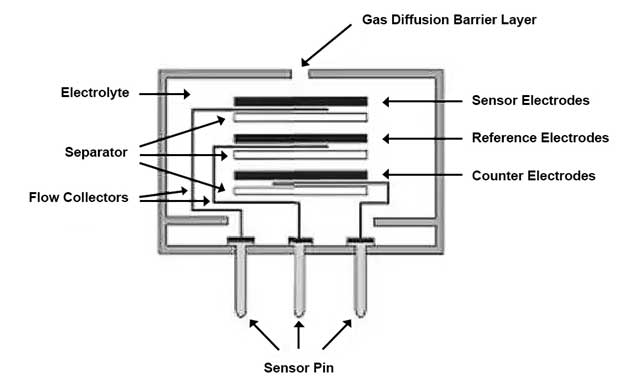

So how does a carbon monoxide gas detector actually “know” when CO is present? Most industrial-grade CO detectors use what’s called an electrochemical sensor. Inside the sensor, there’s a small chamber with two electrodes and an electrolyte. When carbon monoxide gas enters the chamber, it reacts with the chemicals inside and causes a small electric current to flow.

Electrochemical CO sensor cross-section, illustrating electrodes, electrolyte, and gas diffusion layer. Current output is proportional to CO concentration. Image credit: gasdog.com

Here’s the smart part: the strength of that current is directly proportional to the amount of CO in the air. So the more CO you have, the stronger the signal gets. The detector reads this signal in real time, and if it crosses a preset safety threshold, it triggers the alarm. This type of sensor is highly accurate, reliable over time, and doesn’t produce false alarms easily, which makes it ideal for use in busy, high-risk industrial environments.

To know the intensity of the damage this silent killer can cause, know that even a small amount can inflict irreversible brain damage or sudden death. Yes, death! Read on to know why you need to install a CO gas detector in your industry.

Reason 1 – This Threat Is Invisible And Demands Vigilance

Carbon monoxide (CO) gas detectors are necessary in industrial zones because of the basic nature of this gas. Can’t be seen! This hidden peril is dominating the poisonous gas market because it is colorless, odorless, and tasteless, like air. You will think that you are breathing fresh air, but it can be the lethal CO gas that damages your health within seconds.

Human senses are without any doubt incapable of seeing through this looming danger as it goes undetected. Our industry workers are focused on their work in the sounds and smells of various industrial processes. Not a single employee can notice this gas that is invisible in such a busy setting. They won’t get any sensory cues and will be breathing lethal levels of CO.

We are not just saying out of the blue, we have read a report by the Occupational Safety and Health Administration (OSHA) that:

“Because it is colorless, odorless, and non-irritating, people can be exposed to CO without warning.”

This invisibility is the main reason it begins to poison you without you even realizing it. Workers inhale it, which gets mixed up with hemoglobin in their red blood cells. This forms carboxyhemoglobin (COHb) in your body. This means oxygen won’t get transported throughout the body.

Initially, a person won’t understand what is happening to their bodies. They will consider the poison symptoms as common ailments. These common symptoms include flu, fatigue, headache, nausea, etc. As the person doesn’t understand, staying in this state for a bit longer worsens symptoms. In the worst-case scenario, the person will suffer severe incapacitating symptoms such as confusion, loss of coordination, chest pain, and even loss of consciousness.

But this works faster than we think, and before you understand, you are about to collapse. Given the lack of detectability, industrial settings must have a Carbon Monoxide (CO) Gas Detector.

Reason 2 – Almost Every Industry Produces CO Risks

This is not an exaggeration, but the fact that the nature of many industrial operations includes practices that produce CO, whether in small or high amounts. This byproduct of many industrial processes comes from specific sources, and understanding its emission levels is important to stay safe.

First comes the Internal Combustion Forklifts that are usually found in warehouses or factories. These are fueled by propane, gasoline, or diesel, which go through incomplete combustion and produce high amounts of CO as a byproduct. To back this up, we did some research and found that propane-based forklifts produce CO levels ranging from a few parts per million (ppm) to well over 100 ppm. These levels can vary in accordance with engine maintenance, load, and ventilation.

In fact, there is a standard limit to ensure workers’ safety set by OSHA, which is called the permissible exposure limit (PEL), and for carbon monoxide, it is 50 ppm as an 8-hour TWA. In poorly ventilated areas, even an exposure of this amount can be hazardous.

Then comes the industrial furnaces, where incomplete combustion can produce CO. Natural gas, propane, or fuel oil are combusted in these furnaces, and if it is incomplete because of the wrong air-fuel mixture, the burner will malfunction and emit CO. Lastly, there are chemical reactions in industries, for example, in welding processes where oxidation of organic materials takes place, CO gas is emitted in huge amounts.

This makes the installation of a carbon monoxide gas detector inevitable to ensure the safety of industry occupants.

Reason 3 – Early Detection To Prevent Severe Health Consequences

As we have already told you, we know how lethal CO can be for human lives, now it’s about time we talk about preventative measures. As the famous saying goes, “prevention is better than cure.” It is important to install carbon monoxide (CO) gas detectors in industrial zones to reduce the risk of fatalities. These detectors create a chain of measures to avoid risk and long-term health damage from CO poisoning.

For example, it will detect the CO gas levels. Many companies, including Gas Dog, have developed upgraded CO gas detectors designed specifically for industrial environments where early detection can save lives.

These detectors use electrochemical sensors, which are known for their high accuracy and low false alarm rates, making them ideal for noisy, high-interference settings like warehouses or factories. They can detect carbon monoxide concentrations from 0 up to 1000 ppm, with a fine sensitivity of just 1 ppm—so even small leaks won’t go unnoticed. What sets these devices apart isn’t just detection, but smart functionality. Most models come with built-in data logging, which helps safety teams monitor exposure levels over time and analyze trends after an event.

And when danger strikes, they respond fast. With audible alarms, visual warning lights, These devices have pre-determined safety thresholds that, upon breaching, the alarm goes on. And, these thresholds have sensory triggers that turn on the alert mode with loud alarm sounds, loud enough to wake even the sleeping workers in every nook and corner. The alarm makes a sound around 85 decibels that is louder than normal industrial noise levels. Once the alarm is on, the entire setting is evacuated to identify the source of the leak and take necessary steps to make the setting gas-free.

Reason 4 – Legal Responsibility Mandate Action As Per Regulations

We all know that regulatory bodies mandate the installation of a carbon monoxide gas detector in an industrial setting. The occupational safety regulations, like OSHA and EU-OSHA, have also mandated the control of the emission of hazardous gases like CO to ensure safe air quality.

It is the responsibility of industry owners to implement a proper CO monitoring system so that the death toll from CO poisoning is reduced and a safer environment is provided to employees. If the employer fails to implement these safety standards, they will face legal liabilities, lawsuits, and regulatory fines.

Conclusion

Most industries avoid this necessity of safety protocol and face legal actions. Industries simply want to avoid the hassle of installation. However, there are portable CO gas detectors for industrial use that are easy to install and maintain. The main purpose of these regulations is to ensure the safety of your workforce, as every life matters. Protect your workforce before it’s too late. Explore Gas Dog’s range of industrial-grade carbon monoxide gas detectors — built for reliability, compliance, and fast response.